Go Quote Yourself

Posted by Amanda Dimova on

How To Quote Yourself for a Custom Laser Cutting Project

Ready for some math?

We promise it's easy.

We get a lot of quote requests which is unnecessary since our service is designed to let you know exactly how much your project will cost before you even start.

How to calculate PER PIECE pricing, before tiling onto a page

Projects for laser cutting that have large variety of shapes inside are a little harder to calculate the specific PER PIECE cost, so here's a good example of a rough per-piece estimate:

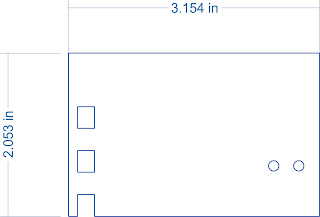

Select the piece you want to price and write down its measurements. This piece is more or less 2"x3" which equals 6 square inches.

We want this piece cut out of thick clear acrylic which costs $64/sft (you can find ALL our prices online in our materials section)

There are 144 square inches in a square foot, so it costs $64/144 square inches or $0.44 per square inch.

Therefore 6 square inches x $0.44 = $2.66 for this particular piece.

And you thought being a designer meant no math!

Optimizing designs to fit in your desired material size

Say you want something in black acrylic and you have a design 2" square.

The smallest size we offer in black acrylic is 12"x12" at $35 for the square foot.

That means you can fit max 6 pieces across and 6 pieces down for a total of $36 pieces per square foot, or so we wish!

You can't tile things right next to each other or to the edge of the material because they may get cut off.

You need to leave some space between the pieces and you need to leave some space from the page edge, we recommend 3mm from each other and 3mm from the edge.

Two methods to optimizing designs to fit in your desired material size

1. Scale down the designs so they are a little under 2" and the whole thing fits into the 12x12 page with 3mm from the edge of the page

2. Reduce the amount of pieces on the page. In this case that would be tiling 5 designs across and 5 down so that 25 fit with plenty of space between.

With the first method you get slightly smaller pieces but 36.

With the second method you get pieces the exact specified size you want but only 25.

36 pieces for $64 = 1.77 cents per piece

25 pieces for $64 = $2.56 per piece

So you can see how the size of your piece greatly changes the price per piece you get, even though the size difference is only a fraction of an inch and the total order costs the same.

|

This screen shot shows proper file layout. The designs are spaced apart from each other and slightly away from the edge of the page. You don't have to use all the same design, it can be whatever you want. |

You can see how you can fit more pieces by shrinking them down. Careful in InkScape when scaling graphics because the outline thickness can also change.

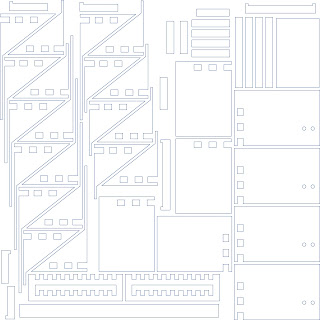

Below is another sample of a file properly set up for laser cutting using just blue lines:

You can see how the designer tiled his parts together but included lots of different kind of parts.

He had this cut in thick clear acrylic for $64 and knew that if he wanted it for $64 he would have to fit all the parts into one square foot. Well done, indeed!